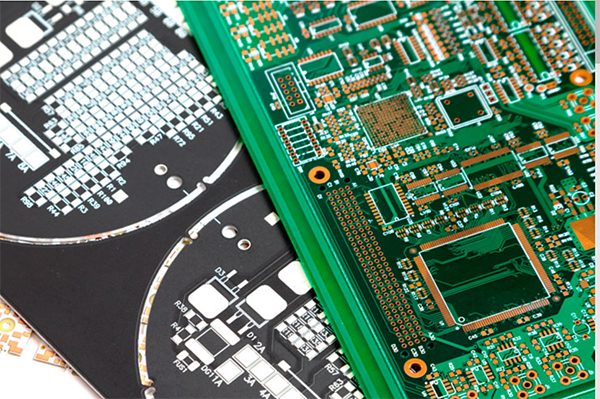

PCB assembling

Enter subtitle here

The Printed Circuit Board (PCB) Assembly Service Can Cut costs and Improve Quality

Imprinted Circuit Board (PCB) Set up is one of the actual required manufacturing procedures with regard to the production of gadgets products. In the previous, consumer electronics oe like producers (OEM) assembled PCBs within house. But due in order to the quick development associated with surface mount technologies as well as innovative manufacturing functions and also equipment, PCB set up is actually now often outsourced to be able to contract electronics manufacturers who else specialize in PCB Assemblage.

You will find decided advantages regarding utilizing a PCB Construction Service. They consist of:one. Less Capital Investment decision. In order to assemble PCBs in-house needs a large capital investment that manufactures facilities, lines and equipment as well as the particular hiring and coaching regarding qualified personnel. Consequently, this can be a lengthy return-on-investment (ROI). Using a good outsourced service simply can make financial and financial feeling.

2. Cost For each Device Benefits. A electronics FACTORY can benefit from "economies involving scale" by using the main city investments made through a PCB Service inside facilities, gear and staff to generate cutbacks throughout cost per device, that can make them much more competing in the market place.

3. Product Style Enhancements. PCB Services occasionally contain electronic design solutions because part of their assemblage expenses. These design providers may verify electronic styles and create suggestions on PCB enhancements, which translates in to superior items with greater quality at a reduced cost for you.

4. The actual Value of Extensive Encounter. Outsourced PCB services have extensive experience in mass-producing PCBs at the cheapest possible cost even intended for tight deadlines. This worth cannot be glossed over.

five. Quality Assurance. In the current aggressive marketplace, quality guarantee will be critical in order for you to reign with unexpected fees and maintain customer happiness. Not really all consumer electronics companies possess the quality systems along with sources as well since the test equipment to ensure the quality of the PCBs. On the other hand, PCB suppliers utilize a number of high quality systems and methods to help ensure quality assurance. Additionally , they have the company relationships in order to procure best quality electronic elements. This particular is critical because to be able to trust the final item, 1 must trust typically the components which are used for you to produce it.

Clients these days use the Internet to help research not just the goods and services of the customer electronics company, but additionally it is business reputation. In case a electronic devices company gets known for generating much less than high quality merchandise, this may result in irreparable damage to their enterprise reputation.

This is main to what a PCB Support can do to get you: lower your charges and guarantee your product or service quality to enhance your own business popularity. It just makes sense to acquire a contract electronics producer to create your PCBs.